- Home

- Flour

Few Words About Flour

Flour is the product obtained by the grinding of grain cereals, such as wheat, rye, barley, corn, etc. Wheat flour is one of the most important foods globally and is the basic ingredient for the making of most kinds of bread and pastries in many cultures. It is the leading source of vegetable protein in human food and is an excellent source of complex carbohydrates and dietary fibre. It is also rich in B vitamins and precious minerals, such as phosphorus, calcium, iron, magnesium, and potassium.

Wheat is one of the first crops to be cultivated on a large scale at the start of civilization and one of the key factors leading to the emergence of city-based societies. Archaeology suggests that this took place in the Middle East area. The discovery that flour can be derived by the grinding of wheat seeds between simple grind stones dates back to around 9,000 B.C.

Wheat kernel anatomy

Wheat kernels have three parts:

1. The BRAN is the hard outer covering of the kernel, high in dietary fibre (mainly insoluble) and trace minerals, as well as the major B-Vitamins. It is included in whole wheat flour.

2. The ENDOSPERM is the largest, inside part of the kernel, containing the greatest share of protein, carbohydrates and iron, as well as the major B-Vitamins (riboflavin, niacin, thiamin). It is also rich in soluble fibre. White flour and semolina are made from the endosperm only.

3. The GERM is the nutrient-rich embryo or sprouting section of the seed, often separated from flour in milling, because its fat content (10%) limits the flour’s shelf life. It contains the largest share of B-Vitamins and trace minerals and forms part of whole wheat flour.

Wheat varieties

There are many varieties of wheat worldwide and these may be classified in terms of their growing season, their colour or their protein content and quality. In general, the harder the wheat kernel, the higher the protein content of the wheat kernel. Based on this, there are 3 basic varieties of wheat:

1. Hard wheat contains a high percentage of protein (gluten) and is used for breads and fine cakes, as well as fresh pasta items

2. Durum wheat is the hardest kerneled wheat of all. In addition to being high protein, its gluten is also inelastic, rendering it ideal for the making of semolina for premium pasta products

3. Soft low protein wheat is paler, with starchy kernels and is used for biscuits, breakfast foods, crackers, etc.

When wheat is ready for harvest, the heads of the grain start to bend the stalks with the weight of the kernels. This indicates that it is time to harvest the wheat. After harvest, the grain is separated from the stalks and chaff. Once the kernels have been separated, they can be ground into flour. There are many classifications for flour, depending on what part of the seed is used and how hard the endosperm is.

Mitsides has a long experience and expertise of around 8 decades is selecting the best quality wheat variety for each purpose. All Mitsides flour is produced and packed at the company’s automated flourmill in old Nicosia, using the latest technology quality controls, comforming to all appropriate standards.

Stage 1 (delivery of raw materials – wheat)

When a wheat cargo arrives at the port, all supplier certificates are checked, while the company’s in house laboratory makes quality checks and sample analysis to ensure than the certificates match the in house analysis. Once all the information and checks are completed and cleared, the wheat is then transferred to the company’s silos, where it is kept until it is ready to go through the milling process.

Stage 2 (pre-cleaning)

Wheat Kernels are initially put through special cleaning machines to remove foreign objects such as like dirt, straw, stones and metals. The kernels are then brushed in order to remove the external part of the bran and any impurities that may be stuck on the kernel. The wheat kernels are then conditioned with moisture in order to soften the bran layer.

Stage 3 (Cleaning part 1)

The silos that hold the wheat have dispenser which may mix various batches of different types of wheat to produce the required mix for the final flour product. During this process the wheat is cleaned once again to remove any remaining small impurities like seeds and broken wheat. It is then brushed again to remove the outer layer and then put through the de-stoner to remove any remaining stones. It is then disposed into a hydrating machine where water is added to bring the wheat to the humidity levels required for processing. The wheat is then stored in the tempering silos for a specific amount of time so that it can absorb the required humidity (wheat tempering).

Stage 4 (Cleaning part 2)

When the wheat has reached the required humidity levels, it is cleaned one final time to ensure that it is 100% clean before the milling process begins.

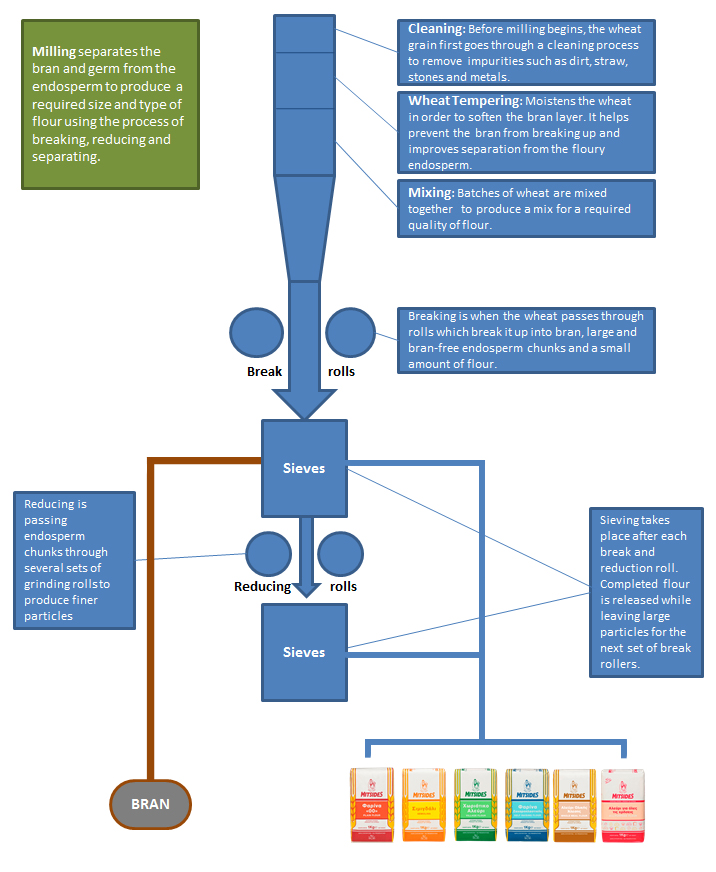

Stage 5 (Milling of the wheat)

Grinding is done in several stages. The wheat first passes through break rolls which breaks the wheat, separating it into bran, and endosperm chunks. It then goes through repetitive reducing and sieving phases, to produce finer particles until the bran is completely separated from the endosperm. The endosperm gives many different types of flour and semolina, while the bran and fine bran are made available for feed stuff.